Zinc sulfate biggest advantage is the current efficiency of up to 100%, the deposition rate, which is the other galvanizing process unparalleled.

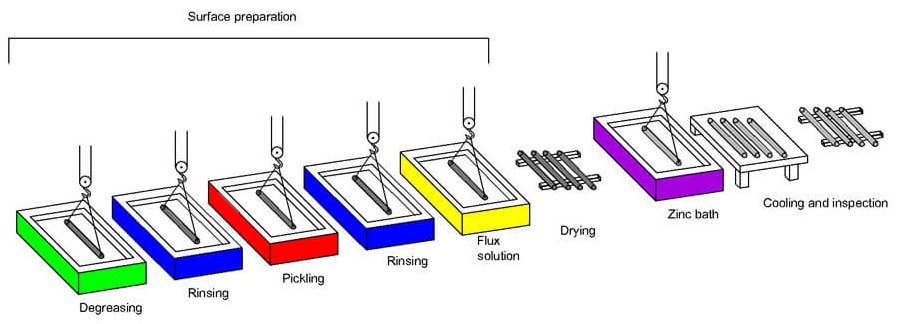

Galvanized pipe process characteristics:

As the crystalline coating is not detailed enough, dispersing ability and poor throwing power, and thus is only suitable for simple geometries such as pipe and wire plating. Sulfate galvanized iron alloy craft of traditional sulfate galvanizing process optimization, leaving only the main zinc sulfate salt, and the remaining components are discarded. In the process of forming a new recipe and adding the right amount of iron, so that the original single-plated zinc alloy metal plating layer is formed. Reorganization process, not only to carry forward the original process high current efficiency, fast deposition rate advantages, but also the dispersion ability and throwing ability has been greatly improved in the past can not be plated complex parts, simple and complex parts can now plated and protective properties increased by 3 to 5 times faster than a single metal. Practice has proved that for wire, pipe continuous plating, coating the grain is more refined than the original, more bright, fast deposition rate. Within 2 ~ 3 min coating thickness to meet the requirements.

Sulfate zinc sulfate zinc alloy to retain only the primary zinc sulfate salt, the remaining components such as aluminum sulfate, alum (potassium aluminum sulfate), etc. can be processed in the bath, was added sodium hydroxide so as to precipitate an insoluble removal; organic additives, then add powdered activated carbon adsorption removed. Tests showed that aluminum sulfate and aluminum potassium sulfate is difficult to completely remove the one-time, affect the brightness of the coating, but not serious, may be accompanied by the consumption, the brightness can be restored at this time plating solution through the processing, according to new techniques additional ingredients required,to complete the conversion.

Sulfate galvanized iron alloy craft up to 100% current efficiency, fast deposition rate is unmatched in any galvanizing process, speed fine tube 8 ~ 12 m / min, the average coating thickness 2m/min, it is difficult to continuous galvanizing achieved. Bright coating delicate eye. According to national standards GB/T10125 "test in artificial atmospheres - Salt spray test" method of testing, 72 h, plating intact, unchanged; 96 h, coating the surface of a small amount of white rust.

Galvanized pipe with galvanized iron alloy sulfate process lies between the trough and the trough are perforated production straight out and no solution or overflow. Each step of the production process from the circulation system components, i.e. the alkali solution tank solution, plating solution, and the passivation fluid, light, not only by the outer loop back leakage or discharge system, located only 5 line cleaning tank, cyclic reuse periodic emissions, especially after the production process without passivation without cleaning the wastewater generated.

Electroplated galvanized pipe with wire plating, as are all continuous plating, but different plating equipment. Wire with its characteristic elongated strip designed plating tank, the tank is long and wide but shallow. Electroplating wire from the hole piercing, showing a shape in the liquid started to keep distance from each other. Unlike wire and galvanized pipe but has its unique slot equipment is more complex.

The tank by the upper and lower parts, the upper part of the plating tank, the lower part of the storage solution circulation tank, the narrow width forming a shape similar to the trapezoidal grooves in the plating bath has a channel running plated galvanized pipe, There are two holes in the bottom of the storage tank is connected to the lower, and the formation of the bath round robin system and sump pump. Therefore, galvanized pipe with wire plating as plating are dynamic in nature, with the difference between the wire plating, plating bath galvanized pipe is dynamic nature.

Tel:

E-mai:

Skype: