ASTM A519 specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished.

ASTM A519 specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished.

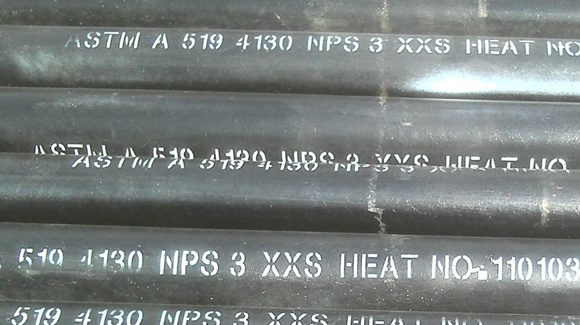

ASTM A519 4130

ASTM A519 SAE 1026

· For mechanical engineering

· For mechanical and pressure use,and also for transporting steam,water,gas and etc.

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel, and if necessary, by subsequently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and properties.

The tubes shall be furnished in the following shapes: round, square, rectangular and special sections. Heat analysis shall be made to determine the percentages of the elements specified. If secondary melting processes are used, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The tubing shall be coated with a film of oil before shaping to retard rust when specified This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

Size range(mm):

· Out diameter:10-324mm

· Wall Tickness:1-30mm

· Length:14000mm max

Grade:

· ASTM A519 1020

· ASTM A519 1025

· ASTM A519 1026

· ASTM A519 1035

· ASTM A519 1045

· ASTM A519 4130

· ASTM A519 4140

Note:

DN — Nominal Diameter

NPS —Nominal Pipe Size

Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

1008 | ≤0.10 | 0.30-0.50 | 0.040 | 0.050 | - | - | - |

1010 | 0.08-0.13 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1018 | 0.15-0.20 | 0.60-0.90 | 0.040 | 0.050 | - | - | - |

1020 | 0.18-0.23 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1025 | 0.22-0.28 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1026 | 0.22-0.28 | 0.60-0.90 | 0.040 | 0.050 | - | - | - |

4130 | 0.28-0.33 | 0.40-0.60 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

4140 | 0.38-0.43 | 0.75-1.00 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Grade | Condition | MPa Tenslle Point | Yield Point | Elongation |

1020 | CW | ≥414 | ≥483 | ≥5% |

SR | ≥345 | ≥448 | ≥10% | |

A | ≥193 | ≥331 | ≥30% | |

N | ≥234 | ≥379 | ≥22% | |

1025 | CW | ≥448 | ≥517 | ≥5% |

SR | ≥379 | ≥483 | ≥8% | |

A | ≥207 | ≥365 | ≥25% | |

N | ≥248 | ≥379 | ≥22% | |

4130 | SR | ≥586 | ≥724 | ≥10% |

A | ≥379 | ≥517 | ≥30% | |

N | ≥414 | ≥621 | ≥20% | |

4140 | SR | ≥689 | ≥855 | ≥10% |

A | ≥414 | ≥552 | ≥25% | |

N | ≥621 | ≥855 | ≥20% |

Please note the meaning of below abbreviation in table 2:

· HR----Hot Rolled

· CW----Cold Worked

· SR----Stress Relieved

· A----Annealed

· N----Normalized

Pipe Type | Pipe Sizes | Tolerances | |

Cold drawn | OD | ≤48.3mm | ±0.40mm |

WT | ≥60.3mm | ±1%mm | |

Tel:

E-mai:

Skype: