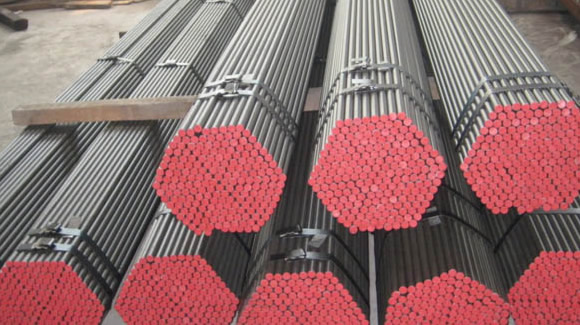

Packing

ASTM A 192M / ASME SA-192M has been approved for use by agencies of the Department of Defense. Consult the DoD Index of Specifications and Standards for specific year of issue which has been adopted by the Department of Defense.

ASTM A192 Boiler Tube

ASTMA 192M / ASME SA-192M Chemical Compositions(%)

| C | Si | Mn | P | S |

| 0.06-0.18 | ≤0.25 | 0.27-0.63 | ≤0.035 | ≤0.035 |

ASTM A 192M / ASME SA-192M Mechanical Properties

| Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation (%) |

| ≥180 | ≥325 | ≥35 |

ASTM A192/A192M seamless carbon steel boiler pipe and superheated tube for high-pressure service

Test:

Hydrostatic or Nondestructive Electric Test

Heat Treatment:Min temperature 650.

Surface Condition:Free of scale,A slight amount of oxidation will not be considered as scale.

Flattening Test,Flaring Test.Flange Test,Hardness Test,Hydrostatic Test

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting. Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles.

Packing:

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Size (mm):

O.D.:6.0-114.0

W.T.:1-15

L:max 12000

Delivery Condition :

As different requirements,It including pickling,etc.

Tel:

E-mai:

Skype: