EN10305-1, E235+N Seamless tube

EN 10305 is for seamless precision steel tube applications.

Yongming offers an extensive range of EN 10305 seamless precision steel tube.

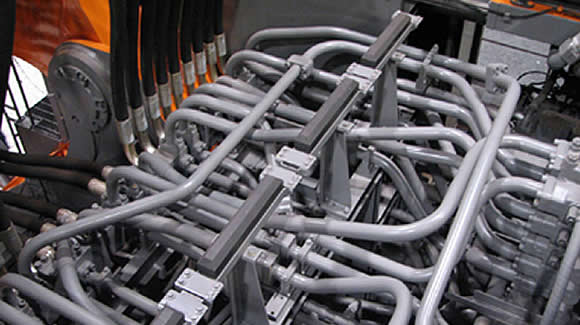

EN 10305 european standard specifies the technical delivery conditions for seamless cold drawn steel pipe of circular cross section used in hyhydraulic and pneumatic power systems.

Applicastion for power steering

Tubes according to this EN 10305 European standard are characterised by having precisely defined tolerances on dimensions and a specified surface roughness. The allowed pressure rates and temperatures are the responsibility of the customer in accordance with the state of the art and in application of the safety coefficients specified in the application regulations, codes or standards.

· EN10305-1 E215

· EN10305-1 E235

· EN10305-1 E355

EN 10305 seamless precision steel tube shall be manufactured from hot finished seamless tubes by cold drawning. Other suitable methods of cold working are permitted. The tubes shall be delivered in the delivery condition +N which means that after the final cold drawing operation the tubes are normalized in a controlled atmosphere.

NBK means protective heat-treating under the non-oxidation enviroment to get a bright and smooth surface for the tubes.

Steel grade | Steel | C(% max) | Si(% max) | Mn(% max) | P(% max) | S(% max) |

E215 | 1.0212 | 0.10 | 0.05 | 0.70 | 0.025 | 0.015 |

E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.015 |

E355 | 1.0580 | 0.22 | 0.55 | 1.60 | 0.025 | 0.015 |

Yield strength | Tensile strength | Elongation |

215 | 290-430 | 30 |

235 | 340-480 | 25 |

355 | 490-630 | 22 |

· The yield point for the annealed (GBK)condition on delivery is at least 50% of the (ultimate) tensile strength. Depending upon the degree of deformation in the drawing operation, the yield point of tubes delivered in the cold-finished/hard (BK)and cold-finished/soft(BKW) conditions, may be increased to a level close to the tensile strength.

· In calculating the yield point, the following values are recommended : cold-finished/hard condition on delivery ≥ 80% of the tensile strength, cold-finished/soft condition on delivery ≥ 70% of the tensile strength.

The tubes are supplied in the following quality grades :

A) precision steel tubes intended primarily for mechanical stressing, without any particular quality requirement and without acceptance test certificate.

B) precision steel tubes intended primarily for mechanical stressing, with special quirement and exclusively with acceptance test certificate.

C) precision steel tubes with special requirement according to section 12. Theses requirements and corresponding tests must be agreed, with the customer having to specify his requirements at the time of enquiry and on ordering.

Term | Symbol | Explanation |

Cold-finished/hard | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

Cold-finished/soft | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

Tel:

E-mai:

Skype: