Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape. Current is then passed between the two edges of the steel to heat the steel to a point at which the edges are forced together to form a bond without the use of welding filler material.

A plate rolled to become a pipe and welded using Electric Resistance Welding process.

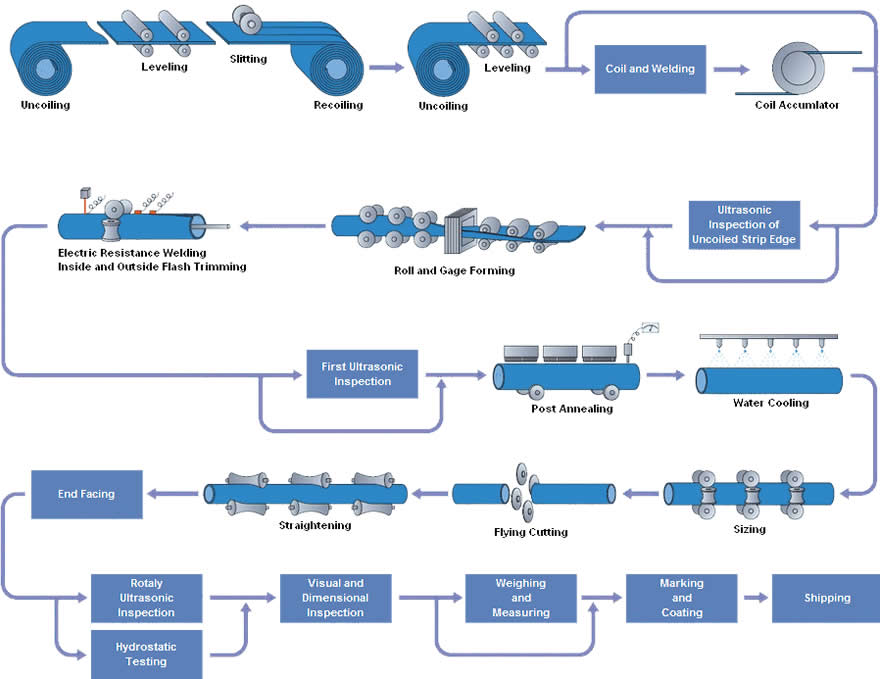

Our manufacturing process generally involves the following stages in a step by step procedure.

HR Coils are slitted to pre-determined widths for each and every size of pipes

The slitted coil is uncoiled at the entry of ERW mill and the ends are sheared and welded one after another. This results in a single endless strip.

The slitted coils are initially formed into U shape and after that into a cylindrical shape with open edges utilizing a series of forming rolls.

In this stage, the open edges are heated to the forging temperature through high-frequency, low-voltage, high current and press welded by forge rolls making perfect and strong but weld without filler materials.

In this stage, the weld flash on top and inside (if required) is trimmed out using the carbide tools.

If required, the welding portion and heat affected zone is put to normalizing and then are cooled down in a air cooling bed.

After water quenching, slight reduction is applied to pipes with sizing rolls.

This results in producing desired accurate outside diameter.

In cutting stage, the pipes are cut to required lengths by flying cut off disc/saw cutter.

This is usually stage, where the pipes ends are faced and bevelled by the end facer.

All these processes are continuous with automatic arrangements. These plain ended tubes further go for processing as per the customer requirements such as galvanizing, threading, black varnishing and more.

Pipe connection is varied, the commonly used have Butt weld, Flanged, Threaded, Socket weld, Glued, Brazed and Grooved end.

Tel:

E-mai:

Skype: