ASTM A178 Welded Boiler Tube

Standards: ASTM A178 (ASME SA178)

ASTM A178/A 178M Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes

Grade: Grade A Grade C Grade D

Size: OD 1/2in-5in(12.7-127mm)

Wall thickness:0.035in-0.360in(0.9-9.1mm)

Different name

Condenser steel tube,heat-exchanger tube,low carbon steel pipe,Resistance welded steel tube ,Bolier flues,Spoerheater flues and safe ends,ERW carbon steel pipes.

Chemical Composition:

Element % | Grade A | Grade C | Grade D |

Low carbon steel | Medium Carbon Steel | Manganess Steel | |

C | 0.06-0.18 | 0.35 Max | 0.27 Max |

Mn | 0.27-0.63 | 0.80 Max | 1.00-1.50 |

P | 0.035 | 0.035 | 0.030 |

S | 0.035 | 0.035 | 0.015 |

Si | ... | ... | 0.10 Min. |

Mechanical Property:

Grade C & Grade D tubes shall conform to the requirements -tensile properties prescribed below:

TensileRequirements | ||

Data | GradeC | GradeD |

Tensilestrength,min,ksi[MPa] Yieldstrength,min,ksi[MPa] Elongationin2in.or50mm,min,% For longitudinal strip tests a deduction for Each1⁄32-in[0.8mm]decreaseinwallthicknessbelow5⁄16in.[8mm] | 60[415] 37[255] 30 1.50A | 70[485] 40[275] 30 1.50A |

From the basic minimum elongation of the following percentage points shall be made

Grade A | |

Tensilestrength,min,ksi[MPa] Yieldstrength,min,ksi[MPa] Elongationin2in.or50mm,min,% | 47[325] 26[180] 35 |

Outside diameter and Wall ThicknessTolerance:

Outside Diameter tol | Wall thickness tol | ||

OD < 50 | ±0.05mm | S < 4mm | ±12.5% |

OD > 50 | ±1% | 4--20mm | +15/-12.5% |

S≧20mm | ±12.5% | ||

ASTM standards:

A450/A450M Specification for General Requirements for Carbon,Ferritic Alloy,and Austenitic Alloy steel tubes.

E213 Practice for Ultrasonic Examination of Metal pipe and tubing.

E273 Practice for Ultrasonic Examination of Longitudinal Welded Pipe and Tubing.

Manufacturing Process: ERW

Heat treatment:

After welding,all tubes shall be heat treated at a temperature of 1650°F(900℃) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650℃)or higher.

Surface Condition:

Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

Mechanical Tests Required:

Flattenting Test/Flaring test/Flange test/Crush test/Tension test/Reverse Flattening test/Hydrostatic or Nondestructive Electric Test

Usage

Used in boiler, superheater, heat-exchanger and pressure equipment in Petrochemical factory, Refinery factory, sugar mill, power plant, power plant, shipbuilding.

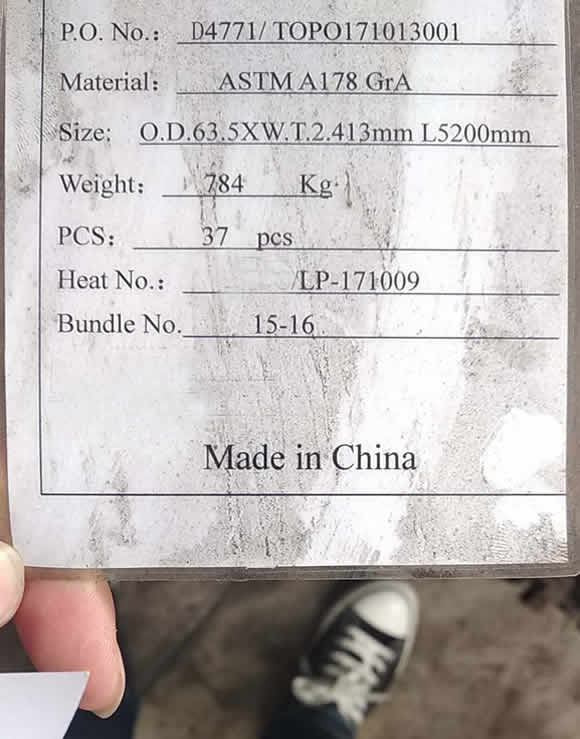

Loading

Bundle package/In budle with plastic bag outside/ In wooden case

Marking as per customer's request

Paint on the pipe as per customer request

4. Pipe caps as customer request

5. As per your requirement

Tel:

E-mai:

Skype: