Pipe elbows are used to be installed between two lengths of pipe or tube allowing a change of direction,usually these elbows distinguished by connection ends.

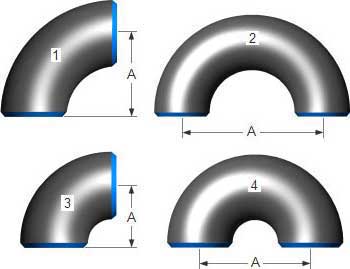

By default, there are 5 opportunities, the 45°, 90° and 180° elbows, all three in the "long radius" version, and in addition the 90° and 180° elbows both in the "short radius" version.

We are engaged in supplying wide range of eblows.

Abrasion resistant piping systems are widely used at coal-fired power plants for a variety of purposes, including the conveyance of coal ash slurry to nearby settling ponds, the transfer of limestone slurry to absorber spray towers for removal of sulfur dioxide (SO2) and hydrogen chloride (HCl) from flue gases and for transporting away the calcium sulfate by-product of the flue gas desulfurization process.

the material is selected accoding to the application use such as high temperature use,sanitary fitting,regular industrial use etc.

Carbon steel: ASTM A234 WPB, WPC, ASTM A420 WPL1, WPL3, WPL6, WPHY-42/46/52/56/60/65/70

Stainless steel: ASTM A403 WP304/304L, WP316/316/L, WP321, WP347 and WPS31254

Alloy steel: ASTM A234 WP1/WP12/WP11/WP22/WP5/WP7/WP9/WP91

Abrasion resistant material:Ceramic lined, Ceramic tile lined , Bi-metal clad pipe,

Manufacturing standards: ANSI, ISO, JIS and DIN.

The ends of pipe elbows may be machined for butt welding , threaded , or socketed , so the elbows are consist of butt weld,thread elbow, socket elbow and other series.

Application of pipe elbows:

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc.

ELL & ELLS

A wing of a building at right angles to the main structure.

A right-angled bend in a pipe or conduit; an elbow.

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 90° or 45° angle, though 22.5° elbows are also made.

+ Pipe elbows size

+ Pipe elbows size

Pressure: SCH5 to SCH160

Size range: 1/2 to 56 inches (DN 15 to DN 1,400mm), 22.5 Deg, 45 Deg, 90 Deg, 180 Deg

External arc length of elbow

Process: butt welding, seamless, threaded , or socketed

Elbows are split into two groups which define the distance over which they change direction; the center line of one end to the opposite face. This is known as the "center to face" distance and is equivalent to the radius through which the elbow is bent.

Here below, for example, you will find the center to face distance of NPS 2 elbows (the A distance on the image)

90°-LR : = 1½ x 2(NPS) x 25.4 A=76.2 mm

180°-LR : = 2 times the 90° LR elbow A=152.4 mm

90°-SR : = 2(NPS) x 25.4 A=50.8 mm

180°-SR : = 2 times the 90° SR elbow A=101.6 mm

The center to face distance for a "long" radius elbow, abbreviated LR always is "1½ x Nominal Pipe Size (NPS) (1½D)", while the center to face distance for a "short" radius elbow, abbreviated SR even is to nominal pipe size.

Note:

90 Degree Elbow – where change in direction required is 90°

45 Degree Elbow – where change in direction required is 45°

L/R - Long radius, S/R - Short radius

Tel:

E-mai:

Skype: